Sintering plate dust remover

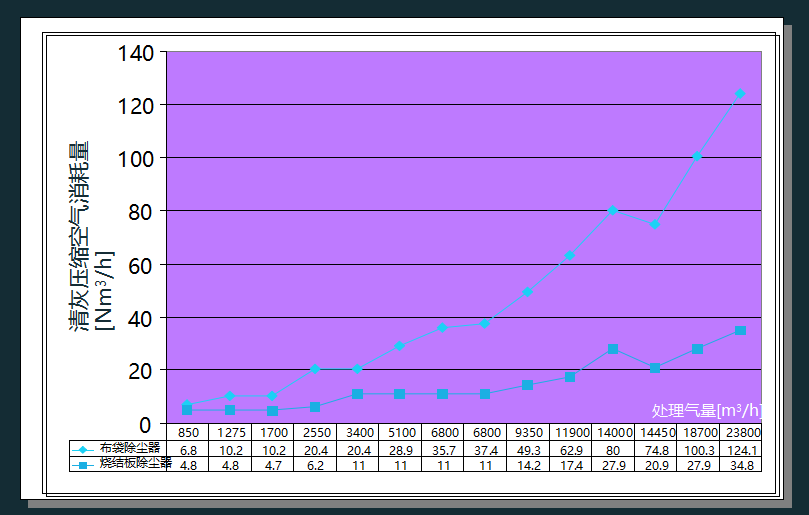

Features and parameters of the super efficient third generation plastic fired plate dust remover:

·The filtering efficiency and precision are higher than those of traditional bag filter, with longer service life and higher return on investment.

Ultra long service life ≥ 10 years.

It is resistant to strong acid and alkali.

It can be quickly disassembled and maintained.

Washable.

Recycling.

Filtering precision: 0.1um, filtering efficiency: 99.999%.

Discharge concentration: 1mg/m ³ (Near zero emission, the industrial dust emission standard is 10mg/m ³)。

It does not contain silicon and can be used in food, medicine and other working conditions with high cleanliness, meeting HEPA cleanliness level.

Characteristic

|

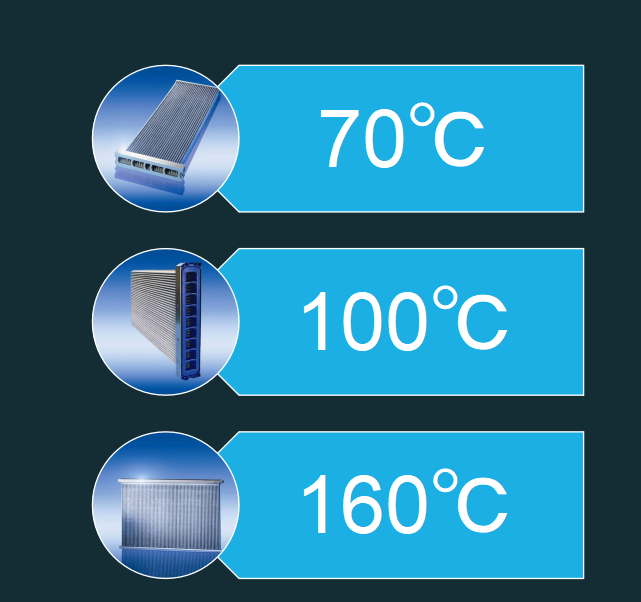

Material characteristics of sintered plate:

|

|

| Sintered boards help increase productivity: ·The use of sintered plate dust remover can meet the requirements of users to improve the quality of their own products to the greatest extent, and further enhance the productivity of users; ·Because of the characteristics of long life, maintenance free and pollution-free of the sintered plate dust remover, the use cost of users is greatly reduced; ·The sintered plate dust remover can meet the current and future environmental protection needs; |

|

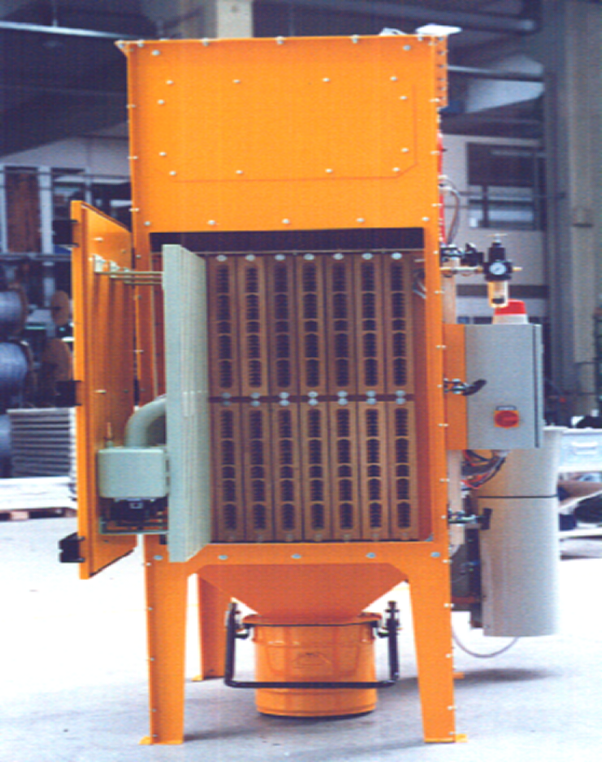

Horizontal installation model

| The compressed air distribution box is also designed and manufactured with modular aviation aluminum alloy, and is equipped with special integrated pulse solenoid valve (aluminum alloy distribution box is only applicable to small machines); |  |

form

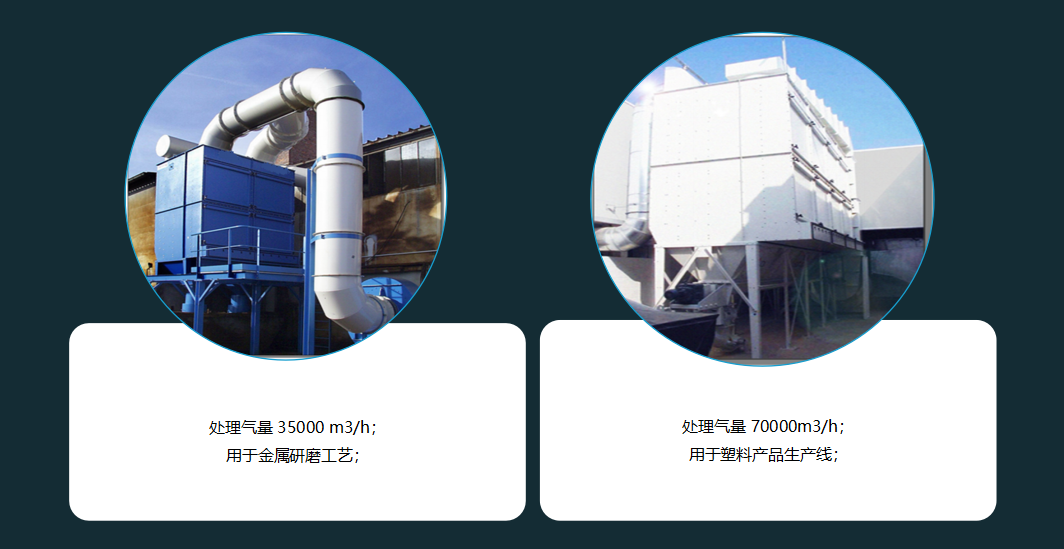

Field case