Pneumatic conveying

The positive pressure dense phase pneumatic conveying system uses compressed gas as the power source as the conveying medium. Forced pneumatic transmission is adopted, and the airtight pressure vessel (sending tank) is used as the transmitter. Generally, the air source pressure is 0.5 Mpa~0.7 Mpa, and the operating pressure is 0.3~0.5 Mpa. The sending tank can only adopt the intermittent transmission mode, and the transmission distance can reach 1000 m. The mode of transporting materials in the pipeline at low speed, in the sand dune state, in the fluidized or agglomerated state is called positive pressure dense phase transportation. High pressure roots blower can also be used.

According to the transportation characteristics, the system can also be divided into positive pressure dense phase dynamic pressure transportation and positive pressure dense phase embolism transportation. Dense phase dynamic pressure transportation refers to the way that materials are transported in the pipeline in the middle low speed sand dune state or fluidization; Dense phase embolism transportation refers to the transportation of materials in the pipeline at a low speed and in a agglomerated state.

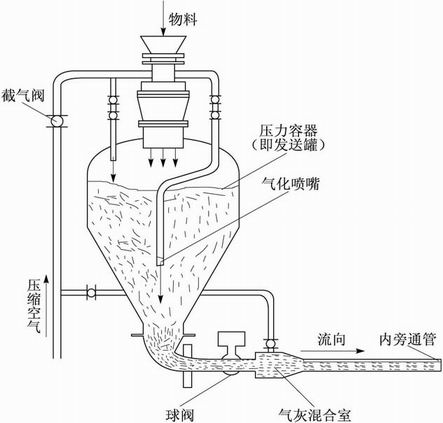

Basic principle of positive pressure dense phase pneumatic conveying system

As a result of the pressure, the material enters the conveying pipe from the sending tank, and the compressed gas forms a pulse air flow (air knife) through the opening and closing of the solenoid valve at a certain frequency. With the air knife pressure greater than the sending tank pressure, the material is cut into a material plug, and the material is pushed forward relying on the static pressure difference before and after the material plug. After the material and gas are separated by the separation device, the material falls into the bin, and the gas is discharged into the atmosphere to achieve transmission.

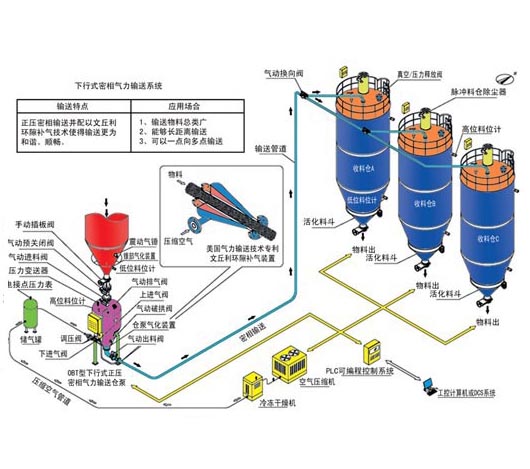

Schematic diagram of positive pressure dense phase pneumatic conveying system

Characteristics of positive pressure dense phase pneumatic conveying system

1. The flow rate is low but the conveying capacity is large, which has little impact on the material quality;

2. The system has high pressure and low air consumption;

3. The control system is automatic, with high requirements for various electrical components;

4. It can feed and unload materials at multiple points;

5. Due to the low material conveying speed, the pipeline and materials are less worn;

6. The delivery tank (also known as the bin pump) is a pressure vessel and a mandatory equipment;

7. The air source is generally screw air compressor, and the post-treatment equipment must be matched;

8. The system is reliable with less maintenance, but requires high quality of operators and technicians;

9. The conveying gas volume is small, and the material gas separation is easy to realize;

10. The working pressure is high, so it can realize long-distance transmission; Super long distance transportation can be realized by using booster.

Basic parameters of positive pressure dense phase pneumatic conveying system

1. Positive pressure dense phase dynamic pressure transmission:

Air speed: 8m/s - 15m/s,

Conveying capacity: 3 - 50th,

Conveying distance: up to 100-1000m,

Air source type: Roots blower, air compressor.

2. Positive pressure dense phase plug conveying:

Air velocity: 4m/s - 12m/s,

Conveying capacity: 2 - 20/h,

Conveying distance: up to 50-200m,

Air source type: high-pressure air compressor.