Pipe chain conveyor

The chain is used as the drive to drive the solid materials to move in the closed pipeline.

During horizontal transportation, solid materials are pushed by the disc in the moving direction. When the internal friction between the material layers is greater than the external friction between the material and the pipe wall, the material moves forward with the disc to form a stable material flow;

During vertical transportation, solid materials are pushed upward by the disc, while the lower feeding prevents the upper material from falling, which generates lateral pressure and increases the internal friction of materials. When the internal friction between materials is greater than the friction between materials and the inner wall of the pipe and the weight of materials, materials move upward with the disc, forming a continuous flow of materials.

Product features

1. The pipeline is completely closed, free of dust and pollution to the surrounding environment, so it is unnecessary to install other dust removal equipment;

2. Low power and energy consumption;

3. Can handle hot, cold, wet, dry, easy

4. Wet or temperature sensitive materials;

5. The materials with good fluidity can be automatically fed;

6. The material is transported smoothly along the pipe with less damage;

7. It can meet the requirements of multi-point blanking and has strong air tightness;

8. Low noise during operation;

9. Convenient on-site installation;

10. The installation space of cross section is saved, and it can be used in places where other types of conveyors cannot be installed;

11. It can meet the requirements of food grade or drug delivery environment;

12. We can design different sizes, materials and structures as required

main parameter

|

Rope chain |

Loop rope chain |

Plate chain |

Optimal conveying speed: 0.1 m/S~0.45 m/s (rope chain: 3~5 m/s).

Main materials: SS, C S. High temperature alloy, wear-resistant alloy.

Conveying distance: the maximum horizontal single machine conveying distance is 80m (rope type 250m), and the maximum vertical height is 50m (rope type chain 20m).

Working temperature: maximum (rope chain 60 ℃, ring chain 180 ℃, plate chain 680 ℃).

Applicable medium: powder, particle and other uniform solid bulk materials, with the maximum allowable particle size of 10mm.

Components

|

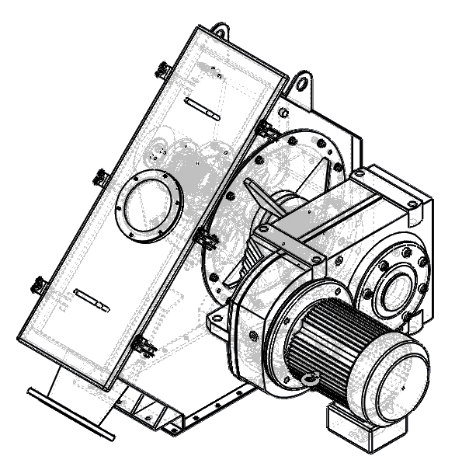

Vertical sprocket box |

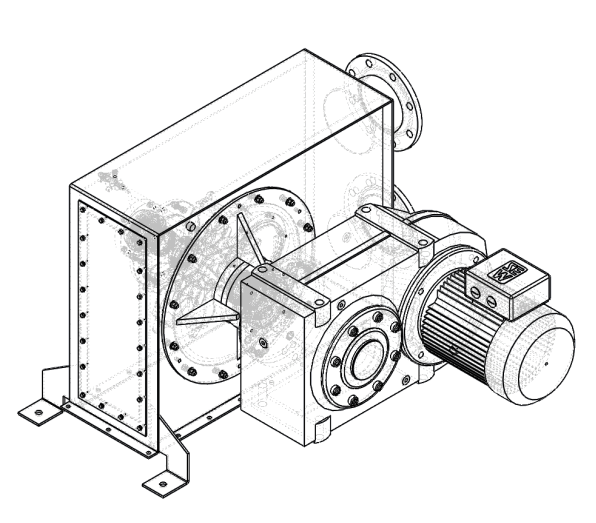

Horizontal driving sprocket box |

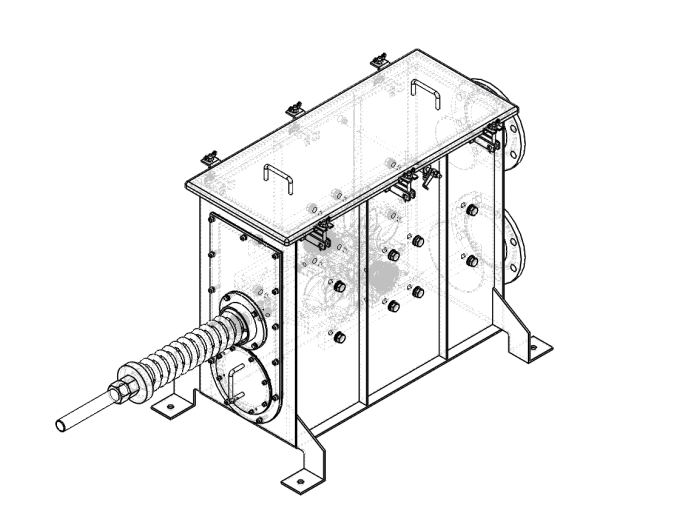

Horizontal driven sprocket box |