Bucket elevator

This series of elevators are suitable for vertical conveying of powdery, granular and blocky materials, and can also lift materials with high grindability. The temperature of materials generally does not exceed 200 ℃, and the maximum lifting height is 40m. Its main characteristics are: wide lifting range, large conveying capacity, small driving efficiency, inflow feeding, gravity induced unloading, long service life, good sealing, stable and reliable operation, convenient operation and maintenance, compact structure, good rigidity, and low operating cost.

Main features of NE bucket elevator:

1. Large conveying capacity. This series of bucket elevator is the largest elevator with similar structure size among similar elevators in China, with lifting capacity of 50m3/h~500m3/h.

2. Wide range of promotion. This kind of bucket elevator requires few kinds and characteristics of materials. It can not only upgrade ordinary powder and small particle materials, but also upgrade materials with high grindability. The temperature is required to be ≤ 200 ° C.

3. The driving power is small. Inflow feeding and inductive unloading are adopted, and the hopper with large capacity is arranged intensively. There is almost no material return and excavation during material lifting, so the invalid power is less, which saves 30% power compared with the chain hoist.

4. The lifting height is high. Plate chain type high strength chain is adopted, and the lifting height can reach 60m under the rated conveying capacity.

5. It is easy to operate and maintain with few vulnerable parts.

6. The bucket elevator has good structural rigidity and high precision. The casing is folded and bulged in the middle. After welding, it has good rigidity and beautiful appearance. Low comprehensive cost, good sealing performance, energy conservation, environmental protection and less maintenance.

Features of main components of NE plate chain bucket elevator:

1. Upper device: rail (double row channel) is installed to prevent chain swing, backstop, hopper rotation, materials blocking the lower casing, and rubber plate is installed at the discharge port to prevent material return.

2. Middle section: some middle sections are equipped with rails (double row sections) to prevent the chain from swinging during operation, and some middle sections are equipped with access doors for maintenance.

3. Lower device: tensioning device is installed, NE15~NE50 is tensioned by spring, NE100~NE800 is tensioned by hammer box.

4. The upper and lower chain wheels are ZG310-570. Overall quenching and tempering, HB229-269 tooth surface quenching HRC40~48.

5. Plate chain: 45 # HRC36~42

Main structure of NE series bucket elevator:

1. Running parts: composed of hopper and sleeve roller chain;

2. Drive device (left and right assembly): composed of drive platform, drive combination (reducer, motor, hydraulic coupling device) and drive chain;

3. Upper device: upper casing, upper cover, discharge port, upper shaft device, backstop;

4. Middle casing: standard section (2m) and non-standard section (1-1.5m), including the middle section with access door;

5. Lower device: lower casing, feeding port, tail shaft device, tensioning device.

Working principle of NE plate chain bucket elevator:

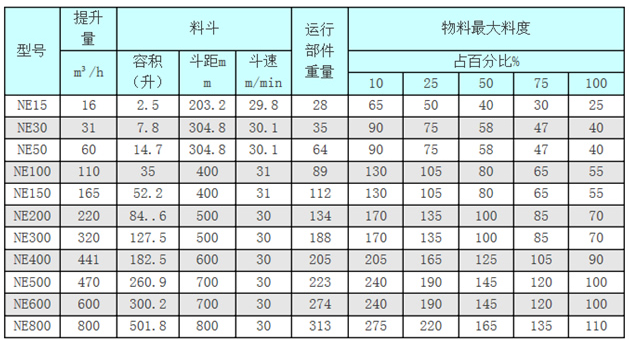

NE plate chain bucket elevator is an inflow type feeder. The materials flow into the hopper and are lifted to the top by the backup plate chain. The materials are unloaded by themselves under the effect of gravity. NE plate chain bucket elevator has many specifications (11 types from NE15 to NE800) and wide lifting capacity; With high production energy and low energy consumption, it can gradually replace other types of hoists. See the following table for main parameters. The machine adopts a fully enclosed casing with low chain speed and almost no material return, so it has less reactive power loss, low noise and long service life.

|

NE technical parameters |

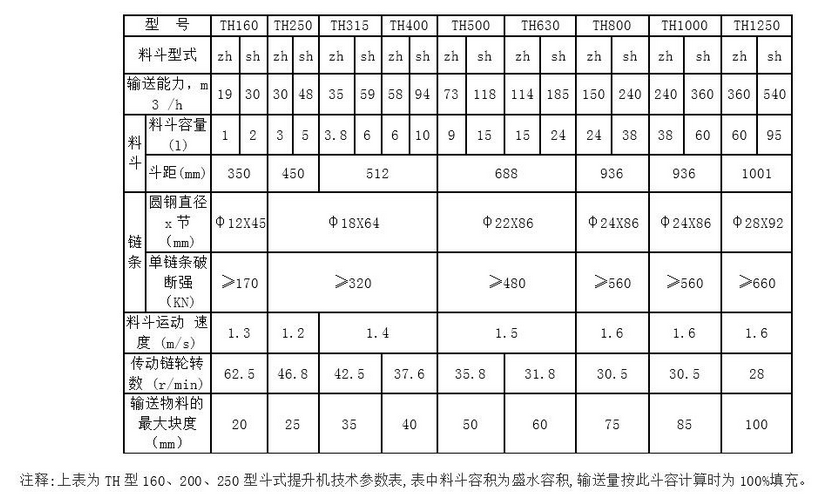

TH bucket elevator |

|

|

|

|

|

|